Lab test plays a crucial role in ensuring the quality and reliability of electronic components and semiconductor materials.

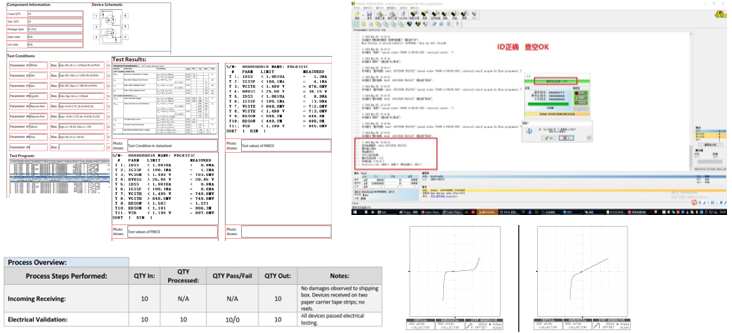

In-house lab test often includes visual inspection and packaging analysis to ensure that the device is correct and in its new and original state.

Visual inspection involves examining the device for physical defects such as oxidization, disformation, discoloration, cracks, scratches, or contamination. This is typically done using microscopes or other magnifying tools.

Packaging analysis involves evaluating the markings, labels, original packing materials, which qualifies the device is correct part and is protected from moisture and other environmental factors.

Third-party lab test is conducted by an accredited and specialized testing company to assess the authenticity, performance, and reliability of electronic products.

It usually involve a range of different evaluations, including external visual inspection, electrical performance test, solderability, decapsulation, RoHS test, X-Ray and software check etc. These tests help to ensure that the device can perform as intended.

When the device is under warranty, it may be possible to request a lab test from the manufacturer.

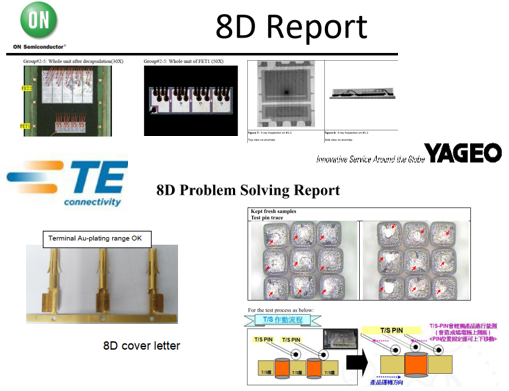

Typically, a manufacturer’s lab test is accompanied by an 8D analysis report. This report helps to identify any defects or define acceptable situations, making it easier to provide an official explanation.

JSD team will always work hard to support your pull-in and push-out needs.

JSD knowledgeable and experienced team always deliver the correct parts.

JSD suppliers normally can support better pricings due to long time cooperation.

JSD have been always supplying only new and original parts since 2004.